Our Products Cannot Be Used As Medicines Directly For Personal Use.

Welcome! For price inquiries, please feel free to contact us through the form on the left side. We will get back to you as soon as possible.

Chemical Processing

Enzymes, nature's biological catalysts, have become essential in modern chemical processing. Their unique ability to carry out highly specific reactions under gentle conditions makes them a powerful alternative to traditional chemical catalysts. This is especially important for industries focused on sustainability. As the need for efficient, eco-friendly, and precise chemical processes continues to rise, enzymes are finding growing applications in areas like pharmaceuticals, fine chemicals, agrochemicals, and material synthesis.

Overview of Enzymes in Chemical Processing

Chemical processing refers to the transformation of raw materials into valuable products through chemical, physical or biological reactions. Enzymes are increasingly used as alternative catalysts for the synthesis, degradation and modification of compounds. They work at low pH and temperature levels, reducing energy consumption and minimizing the generation of hazardous by-products.

Chemical processing enzymes derive from a wide variety of species, from bacteria to fungi and even plants. The advancements in enzyme engineering, such as directed evolution and rational design, have improved their catalytic efficiency, thermal stability and substrate versatility, making them suitable for harsh industrial environments.

Mechanisms of Enzyme Catalysis in Chemical Synthesis

Enzymes accelerates reactions by reducing the activation energy so that reaction rates are increased without being consumed. This unique process depends on the precise three-dimensional structure of the enzyme's active site, which binds to specific substrates and converts them into products. Enzymes operate through a variety of mechanisms. Whether acid-base, covalent or substrate-oriented, enzymes are designed to be highly reaction specific and selective.

Enzymes for chemical synthesis can control many reactions, including hydrolysis, oxidation, reduction, and bond formation. Their inherent regioselectivity and stereoselectivity are particularly important because they enable the production of complex molecules with defined spatial arrangements, which are essential for pharmaceutical and fine chemical purposes.

While existing chemical catalysts work effective, they depend on harsh reaction conditions, including extreme temperatures, pressures and toxic reagents that are harmful to the environment and safety. Enzymes, by contrast, work under mild conditions and exhibit exceptional catalytic activity, and thus represent an ecologically viable alternative to contemporary industry.

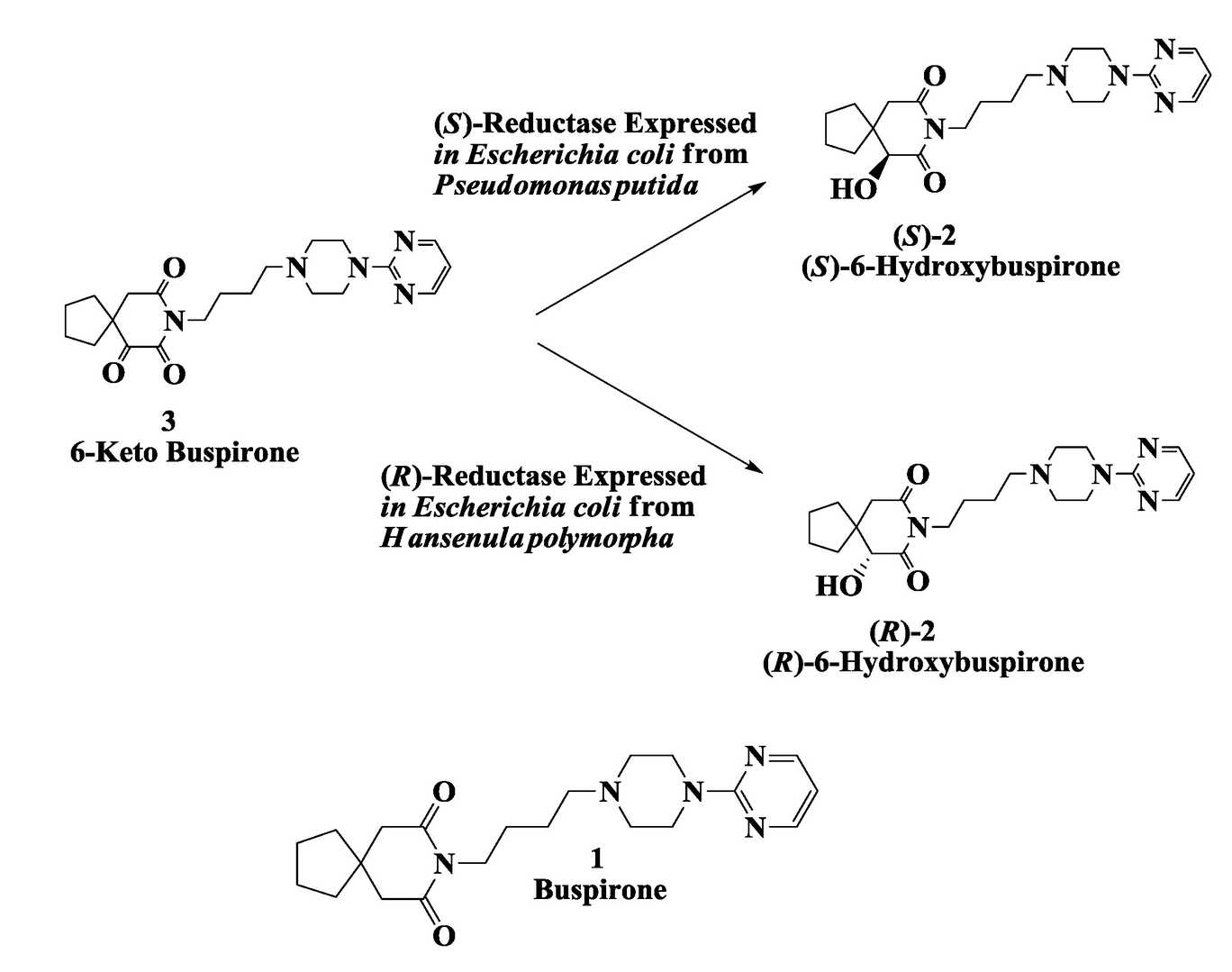

One area where enzymes are particularly excelled is chiral synthesis, an essential process in pharmaceutics. Enzymes are very stereo-specific and can produce pure compounds enantiomerically that would be hard to produce using traditional catalysts. This specificity makes the entire synthesis process simpler, decreases by-products, and reduces the need for additional purification. Such benefits have fueled the widespread use of enzymes in chemical manufacturing, especially for the manufacture of pharmaceuticals, fine chemicals and cosmetics.

Fig. 1: Hydroxy buspirone (antianxiety drug): Enzymatic preparation of 6-hydroxybuspirone (Patel, 2013).

Fig. 1: Hydroxy buspirone (antianxiety drug): Enzymatic preparation of 6-hydroxybuspirone (Patel, 2013).

Advantages of Enzymes in Chemical Synthesis

The application of enzymes in chemical synthesis offers numerous advantages over conventional chemical methods:

- High Specificity: Enzymes possess remarkable substrate specificity, regioselectivity and stereoselectivity, thereby minimizing byproduct production and increasing product purity.

- Eco-Friendliness: Enzymatic reactions usually occur under mild conditions (ambient temperature, neutral pH), requiring lower energy and the need for hazardous chemicals.

- Sustainability: Enzymes are biodegradable and derived from renewable sources, contributing to greener industrial practices.

- Cost-Effectiveness: Enzymes' catalytic effectiveness tends to reduce the need for raw materials and waste, which in many applications means cost savings at large-scale.

- Compatibility with Aqueous Media: Many enzymatic reactions can be performed in water, reducing the use of organic solvents and bringing environmental protection to a whole new level.

Applications of Enzymes in Chemical Synthesis

Enzymes are applied across various industries for synthesizing valuable compounds. Below are some key examples:

Pharmaceutical Industry

The pharmaceutical industry has embraced enzymatic synthesis for the generation of chiral intermediates, active pharmaceutical ingredients (APIs) and prodrugs. Lipases, ketoreductases and transaminases are all frequently used to create enantiomerically pure products. Lipases, for example, catalyze the resolution of racemic mixtures into single enantiomers of chiral drugs such as ibuprofen and naproxen. Ketoreductases, in turn, catalyze the symmetric reduction of ketones into chiral alcohols, key precursors for antibiotics and antivirals.

- Penicillin G Amidase: Used widely to make semi-synthetic antibiotics like amoxicillin and cephalexin, penicillin G amidase (native Escherichia coli penicillin amidase) enables the selective hydrolysis of penicillin G into 6-aminopenicillanic acid (6-APA), a fundamental intermediate in antibiotic production. Using it removes the need for harsh chemical reagents, eliminating waste and making processes more sustainable.

- Trypsin and Chymotrypsin: These proteolytic enzymes play a key role in the synthesis of peptides and in biopharmaceutical manufacturing. Their ability to break peptide bonds in precisely controlled ways makes them a key ingredient in the development of quality therapeutic peptides and proteins.

| Enzymes in Pharmaceutical Synthesis | |||

| Cat. No. | Product Name | Application | Inquiry |

| NATE-1838 | D-Hydantoinase (Crude Enzyme) |

|

Get a quote |

| NATE-0541 | Native Escherichia coli Penicillin Amidase |

|

|

| NATE-1752 | Native Aspergillus sp. Lipase (API) |

|

|

| NATE-1626 | Nitrile hydratase from Recombinant microoganism |

|

|

| NATE-1844 | Halohydrin Dehalogenase (Crude Enzyme) |

|

|

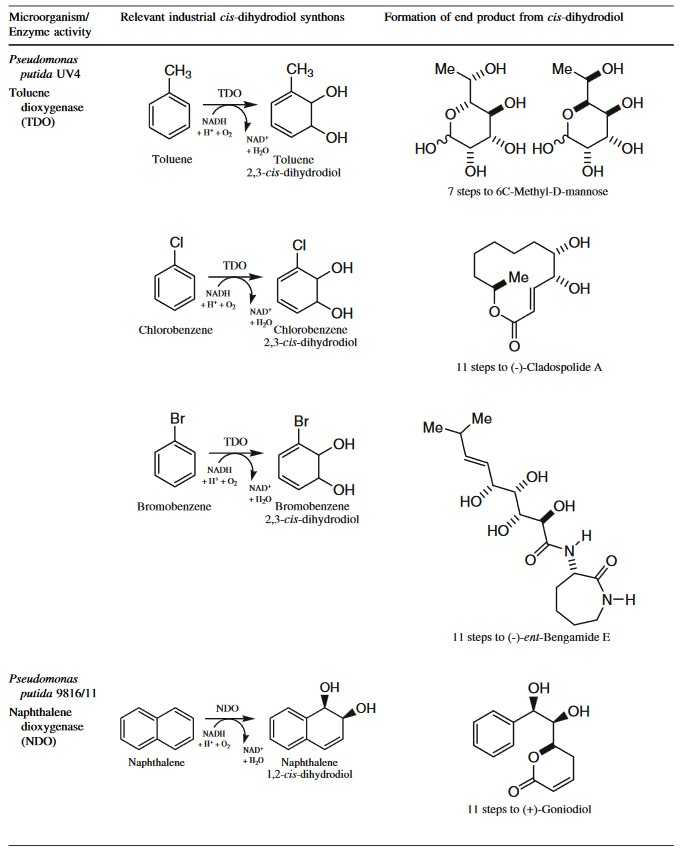

Fine Chemicals

Enzymes are responsible for the production of fine chemicals such as flavors, fragrances and dyes. Lipases, for example, produce ester-based flavors, while laccases contribute to dye synthesis in the textile industry. Enzymatic processes have superior selectivity and fewer environmental side effects than conventional chemical methods.

Fig. 2: Physiologically significant microbial enzymes for the preparation of fine chemicals (Nolan and Conno, 2018).

Fig. 2: Physiologically significant microbial enzymes for the preparation of fine chemicals (Nolan and Conno, 2018).

Agrochemicals

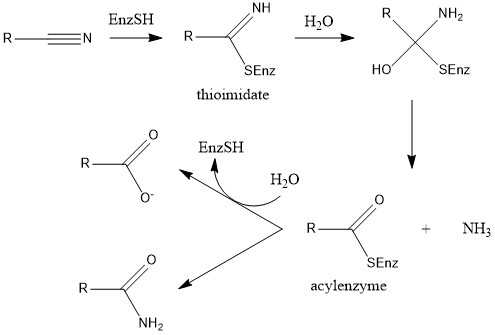

Enzymes are used in the agrochemical industry to produce herbicides, pesticides and growth regulators. Hydrolases and oxidoreductases help create chiral intermediates for these purposes. Nitrilases, for example, hydrolyze nitriles into carboxylic acids, which form the key ingredients of agricultural products.

Fig. 3: The conversion of a general nitrile to either an amide or carboxylic acid is facilitated by nitrilase.

Fig. 3: The conversion of a general nitrile to either an amide or carboxylic acid is facilitated by nitrilase.

Polymers and Bioplastics

Enzymes have found their way into biopolymers and biodegradable plastics. For example, lipases catalyze the polymerization of polyesters, and cellulases support the synthesis of cellulose derivatives for environmentally sustainable packaging materials.

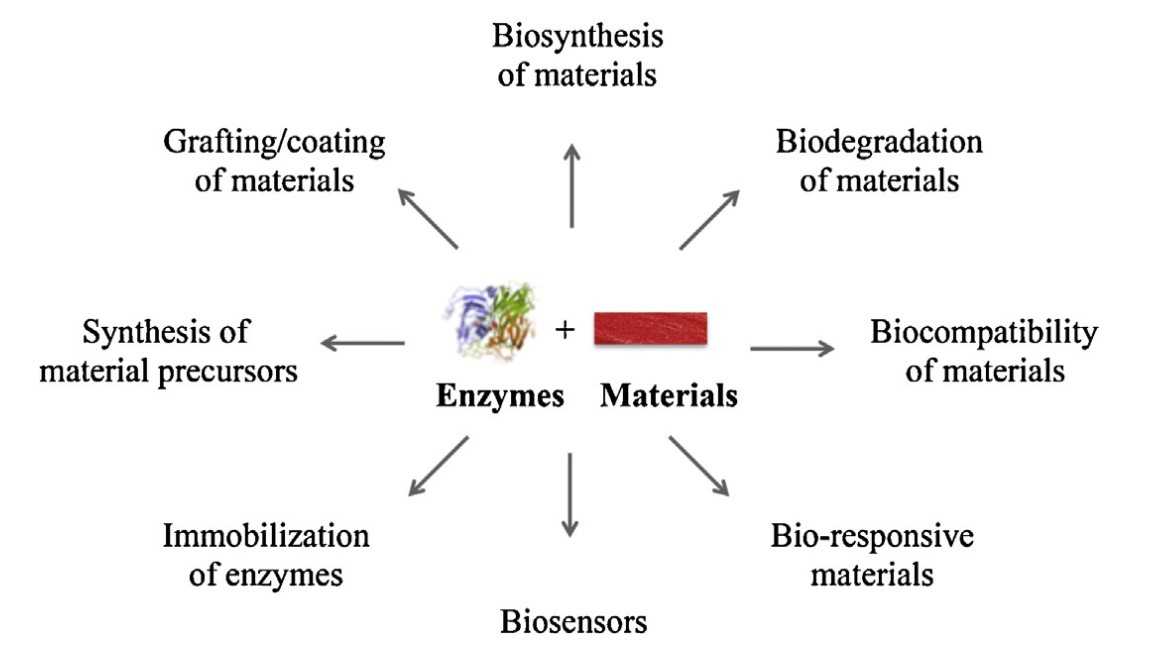

Material Synthesis

Enzymes interact with materials in a variety of ways, making them useful in a wide range of applications. They can catalyze reactions directly on material surfaces to modify its properties, or they can trigger substrates that react with the material. They can also be immobilized or incorporated into materials for functional enhancement. In addition, enzymes enable the enzymatic degradation of polymers into monomers and oligomers. Enzymes also synthesize precursors for material assembly.

Fig. 4: Fields of enzyme application in materials science (Richter et al., 2015).

Fig. 4: Fields of enzyme application in materials science (Richter et al., 2015).

In summary, enzymes are revolutionizing chemical processing by providing environmentally friendly, highly efficient alternatives to current processes. They have applications in a wide range of fields, from pharmaceuticals, fine chemicals and agrochemicals to polymers, bioplastics and materials synthesis. It's not over yet, but enzyme engineering and biotechnology are finally reaching their potential, paving the way for a healthier and more sustainable world. At a time when industries are moving towards sustainable methods, enzymes are sure to play a key role in the development of the next generation of chemical processing technologies.

Partner with Creative Enzymes to revolutionize your processes with cutting-edge enzyme solutions. Contact us today to explore tailored products and expert services designed to meet your unique needs and achieve your goal!

References:

- Nolan LC, O'Connor KE. Dioxygenase- and monooxygenase-catalysed synthesis of cis-dihydrodiols, catechols, epoxides and other oxygenated products. Biotechnol Lett. 2008;30(11):1879-1891.

- Patel R. Biocatalytic synthesis of chiral alcohols and amino acids for development of pharmaceuticals. Biomolecules. 2013;3(4):741-777.

- Richter M, Schulenburg C, Jankowska D, Heck T, Faccio G. Novel materials through Nature's catalysts. Materials Today. 2015;18(8):459-467.

| Catalog | Product Name | EC No. | CAS No. | Source | Price |

|---|---|---|---|---|---|

| EXTZ-485 | Penicillin G amidase | Inquiry | |||

| BIO-1011 | Trypsin | 9002-07-7 | Inquiry | ||

| BIO-1012 | Chymotrypsin | 9004-07-3 | Inquiry | ||

| BODY-2816 | Natural protease-enzyme blend for hair care | Inquiry | |||

| BODY-2815 | Lipase-based enzyme blend for shampoos | Inquiry |

Chiral amino acids production such as D-lysine

Chiral amino acids production such as D-lysine

Penicillin production

Penicillin production

Intermediates production used in drugs or chemicals

Intermediates production used in drugs or chemicals

Intermediates production used in drugs or polymers such as acrylamide

Intermediates production used in drugs or polymers such as acrylamide

Intermediates of herbicide production

Intermediates of herbicide production